Milking Farms’ Electronics

Automatic cleaning of all milking installations. Simple 4 button control. The Base unit is designed as a retrofit unit to replace current washers for stanchion barns and small parlors. The Unit is set up so that the existing external items (drains, divert valves etc.) can be used. The main washer control box houses the water valves, air valves (to activate the vacuum operated air injector) and divider valves. It has relays to run external items such as milk pump, air injector, chemical pumps.

Technical details are at “Service Documentation”.

Specifications:

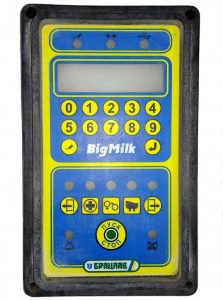

Milking point controller BD-06 provides for fast, easy, efficient milking, and gives you all the information you need in a clear and precise manner.

Technical details are at “Service Documentation”.

Features:

This unit is used for milking systems such as “pipe-line”.

The device consists of the photoelectric sensor and the control unit. The control unit has the plastic sealed enclosure with 3-digit LED display that is clearly visible in the dark. Voltage supply is 15 V. Milk counter reset is done by rising of a magnet to the unit body.

The counter is provided with auto save power mode. It allows to automatically memorize the data in case of power failure. The waterproof performance provides the high reliability and durability of the device.

Specifications:

Full automatic control unit of alley manure removal systems. Controller for automated cleaning barns (cattle kept) machines. Mechanical type is scrapper cleaning. Unit has motor and cleaning unit auto calibration, scheduler, mechanical power overflow control, temperature control etc.

Specifications: